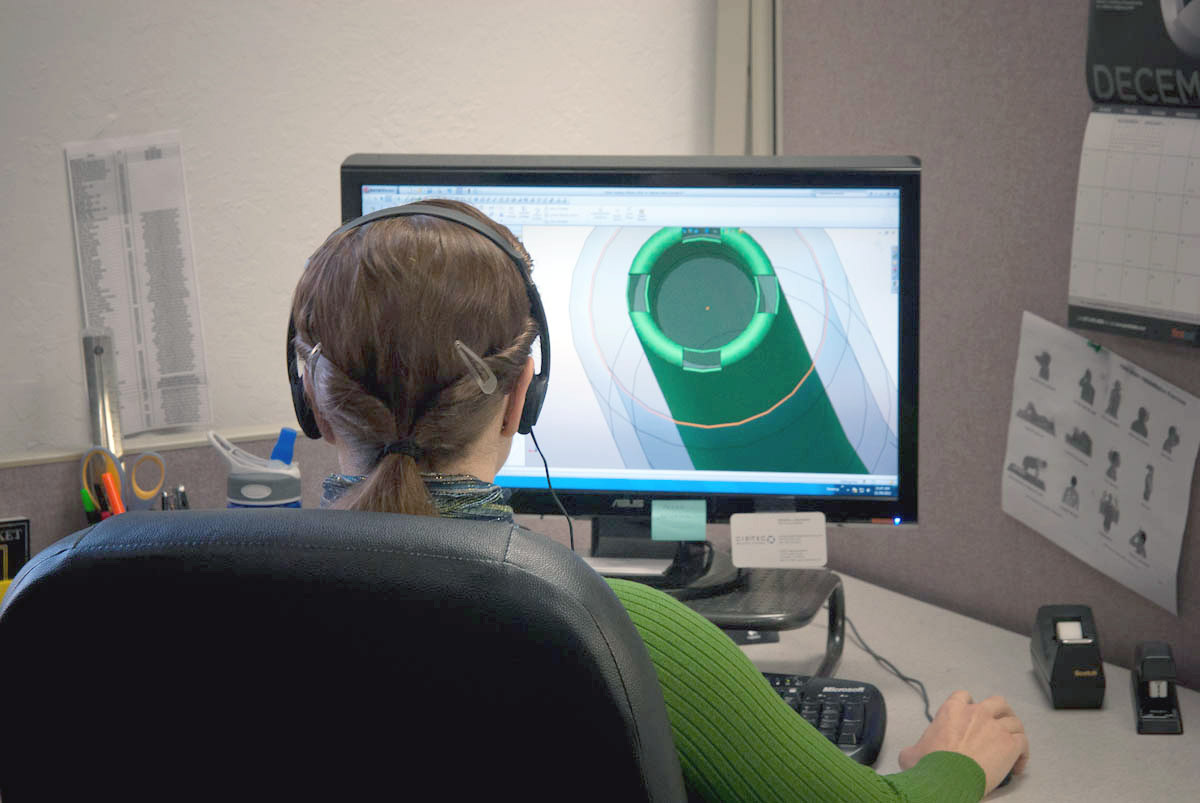

Medical Device Design & Manufacturing

Your Innovation Engine

Cirtec is an industry leader in the design and development of active implants and minimally invasive surgical devices. We are ISO 13485 certified, 21 CFR 820 compliant and we have institutionalized industry-recognized Design for X (DfX) principles under our own proven Five-Phase Product Development Process.

Cirtec offers the following tools, expertise and resources to help make your product technology a commercial reality…

- Flexible and robust design control systems

- FDA-compliant software design controls

- FDA-compliant human factors design controls

- Industrial design

- Human factor engineering

- Rapid prototyping

- 3D printing

- In-house machining

- Mechanical design

- Packaging design

- Design for manufacturability

- Biocompatible materials selection

- Complex mechanism design

- Plastic parts design

- SolidWorks

- Cosmos FEA

- Electrical design

- Altium design software

- Test system development

- Sterilization management

DfX and Five-Phase Product Development Process

Cirtec’s product development teams are fully versed in DfX principles. Namely, we proactively seek ways to optimize your product for quality and regulatory standards, manufacturability, reliable performance and/or end-of-life disposal.

Our proven five-phase design control system ensures practical and progressive innovation over your product’s entire development lifecycle. It encompasses the following activities and deliverables:

Phase 1: Concept Feasibility

- Product development project planning

- Quality planning

- Risk management planning

- Market specification development

- Product requirements specification development

- Identification of applicable standards

- Concept feasibility testing

- Usability and human factors engineering planning

- Software development planning

- Risk analysis

- COGS estimate

Phase 2: Product Design and Development

- Detailed product design

- Component and assembly specifications

- Packaging and labelling specifications

- Design transfer planning

- Supply chain development

- Process development and documentation

- Design and process FMEA

- COGS review

Phase 3: Design Verification

- Design, verification and validation testing

- Biocompatibility testing

- Packaging development

- Sterilization validations

- Updated design and process FMEAs

- COGS review

Phase 4: Production Transfer

- IQ, OQ and PQ

- Final COGS review

Phase 5: Sustaining Manufacturing