Materials Development

Precision manufacturing starts with superior materials development. Cirtec provides comprehensive in-house capabilities and extensive experience guaranteeing this critical step is handled by experts charged with meeting all your required performance characteristics and specifications.

Precision manufacturing starts with superior materials development. Cirtec provides comprehensive in-house capabilities and extensive experience guaranteeing this critical step is handled by experts charged with meeting all your required performance characteristics and specifications.

How we do it:

- Comprehensive materials development in on-site laboratory

- Extensive library of proprietary active formulas

- Optimization of mixing/compounding methods by experienced engineers

- Extensive new compound development and formulation control research and development

- Meeting and exceeding expectations through collaboration with customers

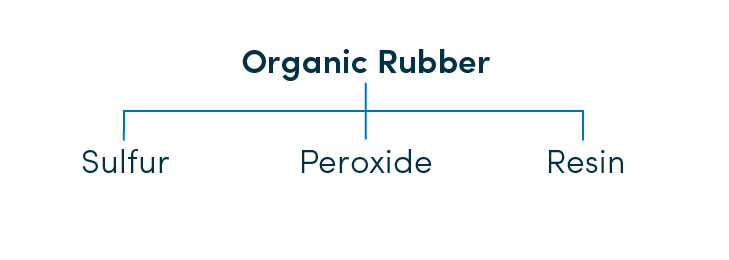

- In-house mixing capabilities for both organic and silicone compounds

- Each batch approved before being sent to production

- Customized color products

- Silicone purchasing power

- Custom formulations

- Pharmaceutical Class VI compounds

- Large numbers of DMF listed compounds from synthetic polyisoprene to butyl-halobutyl rubbers

- Low extractable and leachable compounds

- Highly resealable compounds

- Compounds with low metal ions

Elastomeric Types

Elastomeric Types

- Silicone

- Polyisoprene (IR)

- Styrene Butadiene (SBR)

- EPDM

- Nitrile (NBR)

- HNBR

- Butyl (IIR)

- Halobutyl (CIIR & BIIR)

- Polyurethane (PU)

- Polychloroprene (CR)

- Various Polymer Blends

Lab Equipment

- State-of-the-art analytical laboratory

- Mooney viscometer

- Rubber process analyzer (RPA 2000)

- Oscillating disc rheometer (ODR)

- Moving die rheometer (MDR)

- Universal testing machines

- Compression relaxation testing

- Back pressure tests

- Durometer/hardness tester

- pH meter

- Ultraviolet/visible spectrometer (UV-VIS)

- Atomic absorption spectrometer (AA)

- Tubiditimeter

- Fourier transform infrared spectrometer (FT-IR)

- Differential scanning calorimeter (DSC)

- Thermogravimetric analyzer (TGA)

- Dynamic mechanical analyzer (DMA)

- Spectrophotometer

- Dielectric tester

- XRF analyzer

- Pull tester

- Wick tester

Specifications

Specifications

- Compression Set

- Tear strength

- Tensile strength

- Hardness

- Elongation

- Modulus

- Aging properties

- Swelling

- Rheology – variable temperature analysis

- Rheology – frequency/strain/temperature sweeps

Capabilities

- Tests as per USP standards

- Chlorination

- Surfactant treatment

- Parylene coating

- Siliconization and silicone level analysis

- Precision slitting capabilities with dimensional check

- Precision auto high-speed vision inspection systems

- Elastomer-to-elastomer bonding and assembly

- Leak testing

- Comprehensive milling and mixing capabilities

- Lab-scale internal mixing for quick prototyping

- Mills 72” hydraulic blending (with stock blender)

- Four mixing lines

- Dedicated medical mixer

- Material mixers 90 to 110 liters

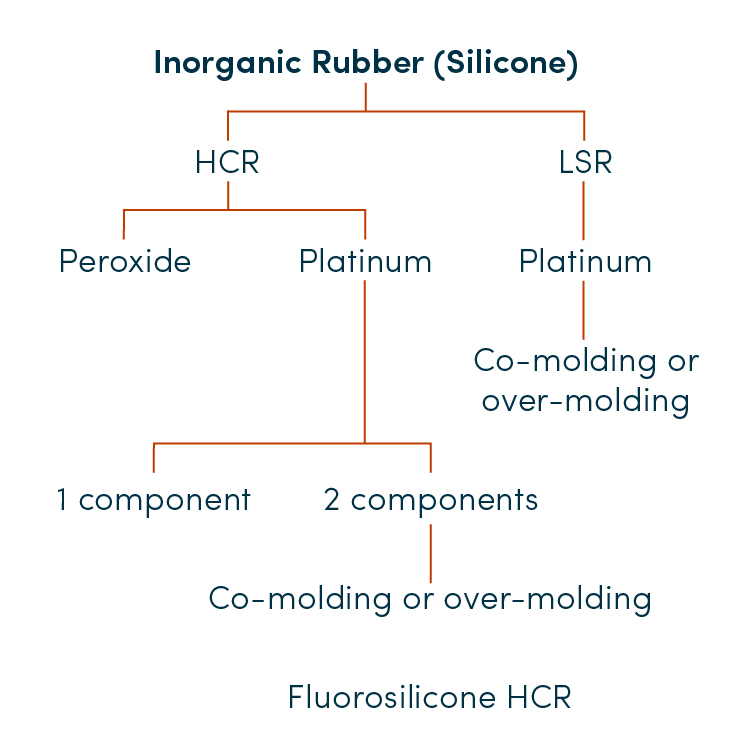

Curing Processes